* Updated points of Haco-chan-2

Feeding system from roller to liner slider to get accurate length.

Accurate length cutting against even strong coil winding trend.

3. Same loss cutting for strip flat matrix tape between this machine and normal handy cutting device.

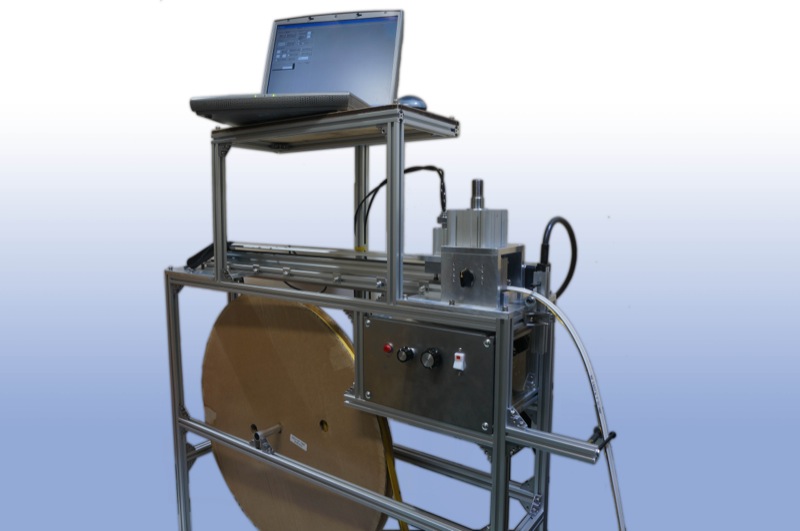

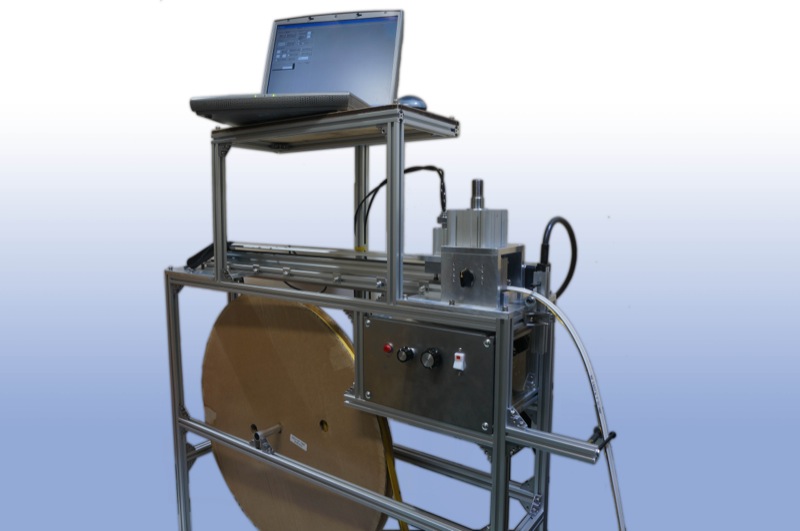

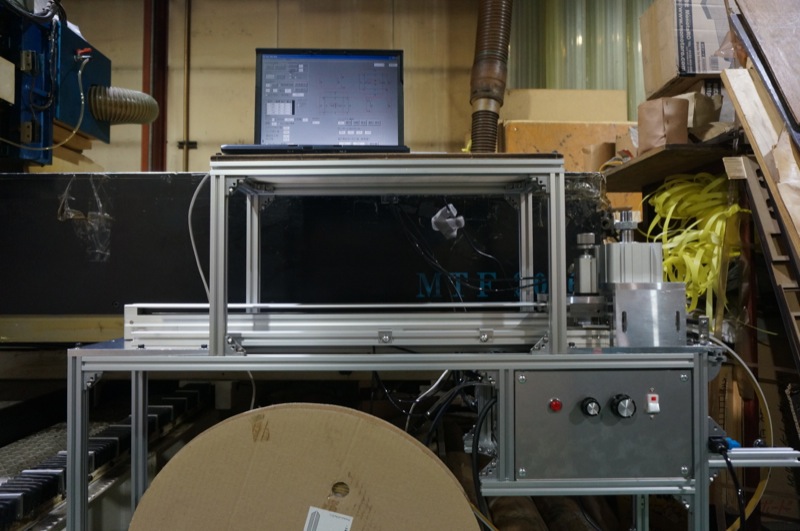

Machine size becomes bigger than Haco-chan-1. But PC and tape feeder become one body that save space totally.

Back ground of this machine debut.

CAD counter plate becomes popular. On the other hand, Matrix tape also has advantage for itself.

It is easy handling, accurate transferring to cutting plate and quick adjustment after actual die cutting trial that is difficult for CAD counter plate. But it takes long idle time to cut by manual cutter beside the die cutting machine.

|

|

|

Haco-Can-2 is light weight and compact size. System component is PC and machine only. Controller and motor driver is installed body inside.

Width: 600mm Length: 200mm Height. 1000mm Weight; 20kg (include with material and PC)

|

|

You can operate operation panel and PC program easily.

You can arrange the cutting speed and feeding speed even on working.

Red button can decrease feed motor speed on setting the tape and it works as emergency button to stop working.

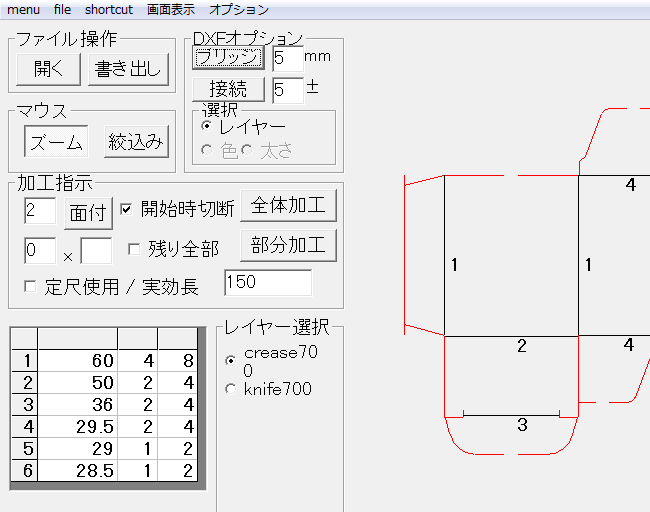

Machine can work with DXF and DDES data. DXF data with bridge space can be connected automatically. Creasing information must be identify by layer or color.

|

|

|

Coil matrix tape is best, but strip flat tape also is available. Alarm sound from PC notices at the material lack timing about strip flat material. You can re-start push button after setting new strip tape.

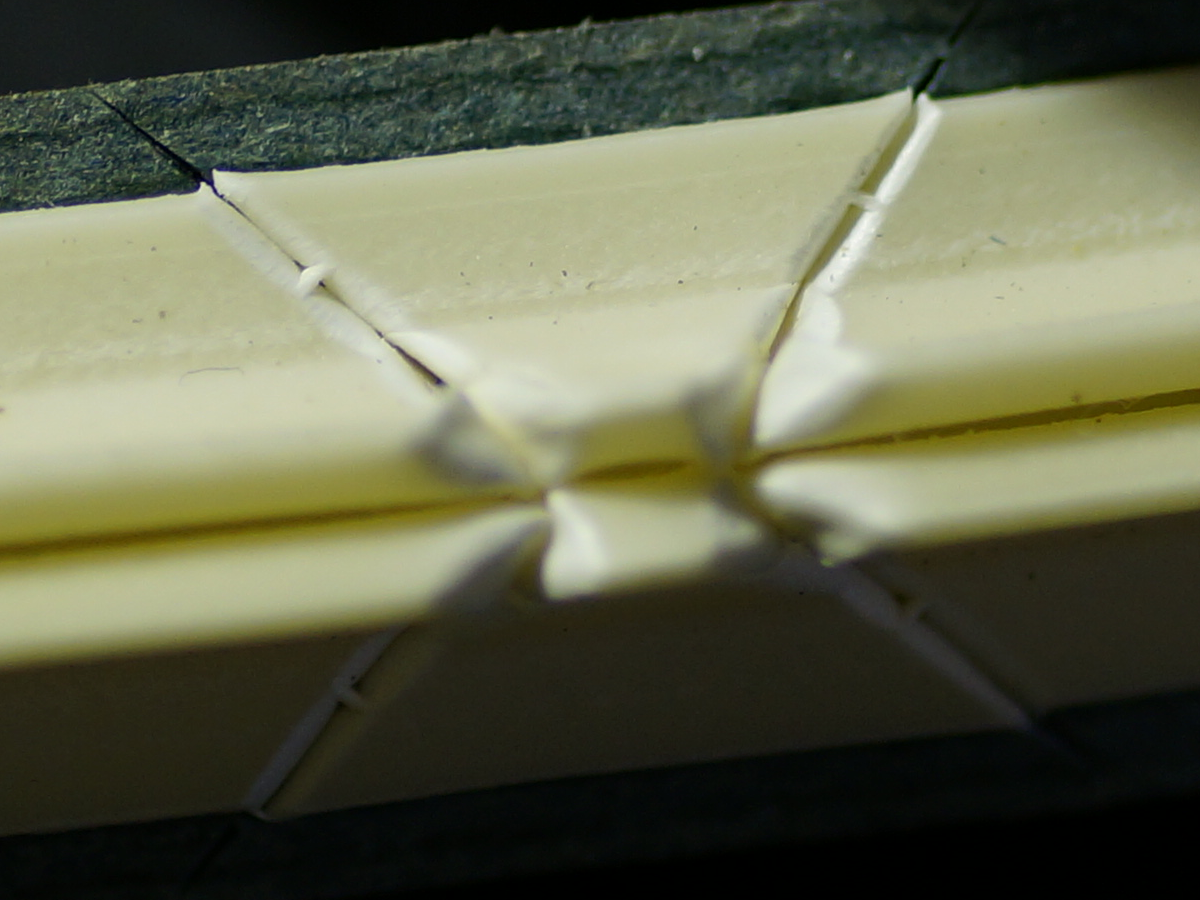

Machine has small steel rule die for matrix cutting. It has micro nick to keep long feeding and to remove easily each other. PC display shows the CAD drawing that each creasing is given the number depend on length automatically. You can apply cut matrix tape depend on each number on drawing.

|

|